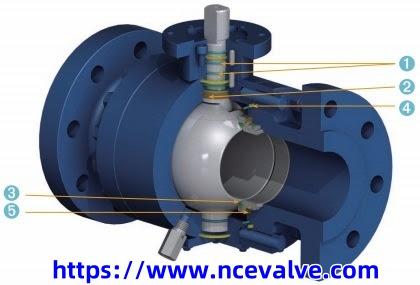

Within the demanding world of industrial valve manufacturing, Naishi, a leading Trunnion Mounted Ball Valve Factory, has built its reputation on material innovation and structural precision. Each valve produced is the result of advanced metallurgy, precision machining, and comprehensive automation, ensuring resilience under extreme thermal and mechanical stress. From high-pressure oil transport to petrochemical refining, the combination of robust alloys and engineered design gives every unit superior sealing stability and long service adaptability.

The foundation of quality begins with the science of materials. Each metal component undergoes precise chemical composition adjustment to ensure uniform hardness, corrosion resistance, and weld integrity. By employing enhanced alloy formulations, the structure resists deformation under fluctuating temperature and pressure cycles. Surface treatments further refine microstructure density, minimizing fatigue and friction loss. These procedures result in a durable body capable of sustaining reliable flow control in high-demand environments while preserving operational smoothness.

Testing standards play an equally vital role in confirming the reliability of each unit. The inspection process extends beyond traditional dimensional verification, incorporating ultrasonic scanning, microstructure analysis, and controlled fatigue simulation. These multi-layered tests replicate real operating conditions, allowing engineers to identify and correct microscopic imperfections before assembly. Through this approach, manufacturing transforms from routine production into a predictive system where every component's future performance is statistically validated. The result is consistency that supports the safety and reliability required in energy infrastructure systems worldwide.

Automation integrates seamlessly into this structure of reliability. Robotics manage welding, polishing, and inspection with synchronized precision, ensuring that human expertise is applied to innovation rather than repetitive tasks. Automated production lines guarantee consistent alignment, weld penetration, and sealing accuracy, all maintained within micro-tolerance levels. The combination of machine precision and digital process monitoring creates a feedback cycle where each improvement reinforces the next, allowing the entire operation to evolve continuously without compromising speed or craftsmanship.

Precision engineering, however, extends beyond machines. The philosophy of automated control at Naishi reflects a deeper belief in repeatable excellence, where every mechanical motion is both measured and purposeful. Software systems record and analyze data from every production stage, transforming it into insights that guide process optimization and material utilization. This data-driven approach eliminates waste, improves yield, and establishes a transparent quality trail that customers can depend on.

As a technologically advanced Trunnion Mounted Ball Valve Factory, Naishi remains committed to developing valves that unite automation, testing excellence, and material strength in one cohesive framework. Each valve produced is a statement of industrial confidence, combining endurance and accuracy for complex engineering challenges. Learn more at https://www.ncevalve.com/product/fully-welded-ball-valve-1/fully-welded-trunnion-mounted-valve.html